SPICE simulations are a well-known simulation tool for accurate circuit design. However, for those who still rely on intuition and experience, it’s overdue to embrace PCB simulation software and explore its potential to promote less faulty and more sustainable designs.

While the sustainability agenda has primarily focused on large cooperations and companies, small and medium-sized enterprises also have a significant role to play in reducing their carbon footprint. Simulation software offers a great value for promoting sustainability in the manufacturing industry by addressing areas such as efficiency, impact, waste, design reliability, and supply chain resilience.

SPICE simulation in particular has the potential to play a crucial role in promoting sustainable design practices for electrical products. With increasing demand for energy-efficient and eco-friendly products, it’s essential for engineers to adopt new technologies and strategies to meet these expectations. How, you might ask? Let’s find out.

What’s so special about SPICE simulation?

SPICE simulation simply revolutionizes electronic circuit design and analysis. Its ability to accurately model intricate circuits empowers engineers to analyze performance parameters such as voltage, current, power dissipation, and frequency response.

By simulating circuits before physical prototyping, fabrication or manufacturing, SPICE simulation reduces both time and costs associated with design iterations. This iterative process aids in:

- Design optimization facilitated through the evaluation of different alternatives and parameter values, ensuring optimal circuit performance and adherence to design requirements.

- Troubleshooting and debugging circuit issues, as well as accelerating the identification of root causes.

- Wide-ranging applications in analog, digital, power, RF, and mixed-signal electronics making SPICE simulation a versatile platform for streamlined circuit development.

Some of the types of simulation that can be performed include:

Transient

Analyzes AC circuits, as well as circuits with nonlinear components and arbitrary waveforms

- Calculates circuit response in the time domain

- Used to understand how a circuit responds to changes in input signals

DC Sweep

Calculates the DC current in a circuit as a function of DC input voltage

- Input voltage is swept across a range of values and current values show on a graph

- Used to understand how changes in input voltage affect circuit behavior

Frequency Sweep

Calculates the circuit response in the frequency domain, such as for a filter or impedance-matching network

- Calculates the circuit’s response at different frequencies, showing how the circuit behaves over a range of frequencies

- Used to understand how the circuit behaves in different frequency ranges and for designing filters and other frequency-dependent components

Parameter Sweep

Involves varying a specific parameter in the circuit across a range of values as part of another simulation

- Used to experiment with different component values and understanding how changes in these values affect circuit behavior

- E.g. performing a parameter sweep to investigate how changing the value of a resistor affects the circuit’s performance

By simulating the behavior of the circuit under different conditions, SPICE simulations can help engineers and designers to optimize circuit designs, identify potential issues and improve overall circuit performance. And the best part? It’s a cost-effective method to test and validate new designs without the need for physical prototypes.

PSpice to the rescue

Cadence® PSpice® is the superhero variant of the SPICE simulator that offers an array of enhanced features and capabilities for PCB design. PSpice extends the functionality of SPICE and provides designers with a comprehensive toolset to simulate, analyze, and optimize electronic circuits.

Mixed-signal simulation

Now, you may know that PCBs often play host to a mix of analog and digital circuitry. One notable feature of PSpice is its ability to perform mixed-signal simulations, allowing you to simulate the interaction between these different domains accurately.

By combining analog and digital simulation capabilities, PSpice enables designers to validate the integrity of mixed-signal designs, ensuring proper functionality and minimizing potential signal integrity issues.

Let’s say, you’ve got this complex design, maybe an IC or a SoC, and you don’t want to get bogged down in the nitty-gritty transistor-level details.

PSpice supports behavioral modeling, allowing designers to create and simulate complex circuit components using high-level behavioral models instead of detailed transistor-level representations.

Behavioral models can significantly reduce simulation time and enable rapid prototyping and optimization of complex designs.

Optimization techniques

PSpice truly brings the cool optimization tricks to the table. It incorporates advanced optimization techniques that enables you to refine your designs for specific objectives. You can define optimization goals, such as minimizing power consumption, maximizing signal-to-noise ratio, or meeting specific performance criteria, and PSpice will automatically adjust design parameters to achieve those goals.

This optimization process can help identify the most efficient component values, optimize circuit layouts, and fine-tune designs to meet desired specifications.

Say goodbye to manual trial-and-error!

Advanced analyses

Design for real-world scenarios and applications can be a real challenge, right? With PSpice, you are already one step ahead.

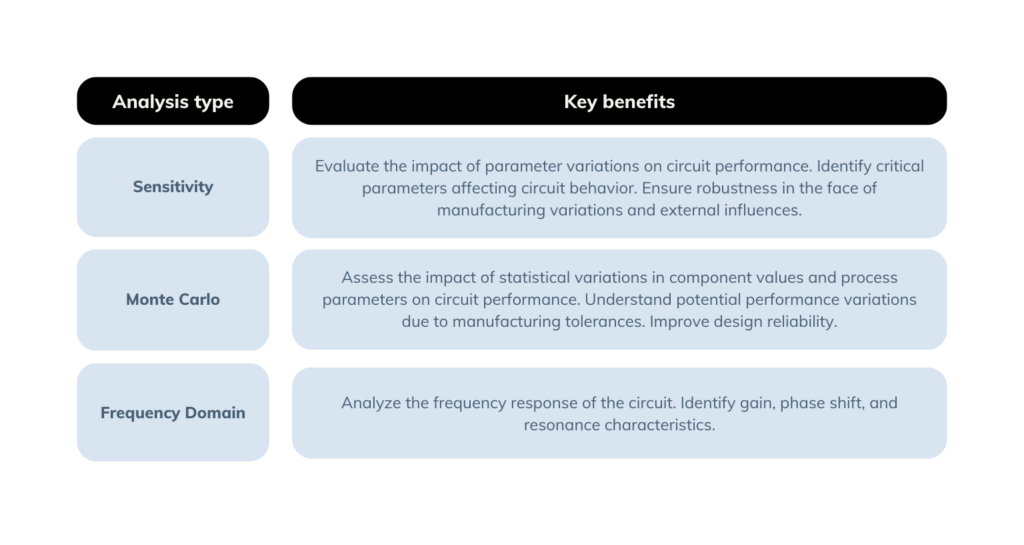

Amongst many standard types of analyses, such as transient and frequency domain analysis, PSpice also facilitates more advanced analyses, such as sensitivity analysis, Monte Carlo and Frequency Domain analysis.

These analysis types ultimately help ensure robustness in the face of manufacturing variations and external influences, leading to more reliable and resilient designs.

By leveraging the advanced capabilities of PSpice, you can gain a deeper understanding of their circuit designs, evaluate performance under various conditions, and optimize designs for efficiency, reliability, and functionality.

How does PCB simulation relate to sustainability?

In the pursuit of minimizing e-waste, PCB designers hold a pivotal role as the vanguards of environmentally sustainable practices. The utilization of SPICE simulation offers an advanced arsenal of tools to achieve this crucial objective. So, as promises – here are 3 ways to unlock the power of SPICE simulation:

1. Early design validation and fault analysis

The framework is quite simple:

Early design validation and fault analysis

=

Less costly rework and hardware failures.

Picture this: you’re in the early stages of designing a PCB. You are reusing a previous design, making adjustments and alterations. And you have enough experience under your belt to feel confident about the design – or you might just be in a time crunch. Let me challenge you on this.

Instead of jumping straight into physical prototypes or moving on to fabrication and manufacturing – risking costly rework – let SPICE simulation come to the rescue! You can simulate the behavior of your circuit under different conditions. It’s like having a crystal ball that helps you spot potential issues before they become real-world headaches. By catching those problems early on, you can save resources, minimize waste, and ensure your design hits the mark from the get-go.

Interested in learning more about this?

I hosted a webinar about the undeniable advantages of implementing simulation to your design process. In just 15 minutes, you will get real-world cases and data on the impact of simulation.

Because let’s face it – we all know that even the most meticulously designed circuits can sometimes encounter unexpected hiccups. The ability of SPICE simulation to analyze circuit behavior under fault conditions proves invaluable in reducing e-waste. By simulating fault scenarios such as short circuits, open circuits, or component failures, designers can identify weaknesses in the design and implement appropriate remedial measures. This proactive approach significantly mitigates the risk of field failures, prevents premature discarding of devices, and contributes to the overall reduction of e-waste. And saves money and working hours.

2. Energy efficiency and power management

Analyzing your design allows for the identification of power-hungry components or circuit sections, enabling you to implement energy-efficient design strategies such as power gating, clock gating, or voltage scaling. By reducing unnecessary power consumption, designers can extend battery life, reduce energy waste, and promote sustainable electronics.

PSpice also enables simulation and analysis of dynamic power management techniques such as dynamic voltage scaling (DVS) or dynamic frequency scaling (DFS). By dynamically adjusting voltage levels or operating frequencies based on workload demands, designers can achieve significant energy savings without sacrificing performance. PSpice provides a platform for evaluating the effectiveness of these techniques, allowing you to minimize energy consumption.

Efficient thermal management is essential for maintaining the reliability and longevity of electronic devices. Excessive heat not only affects performance but also leads to energy wastage. PSpice facilitates thermal analysis by simulating and predicting temperature profiles within the circuit. By identifying hotspots and areas of inefficiency, you can optimize heat dissipation strategies, improve cooling mechanisms, and reduce energy loss due to thermal inefficiencies. This proactive approach to thermal management ensures energy-efficient operation while extending the lifespan of electronic devices.

3. Reusability and lifecycle assessment

In the quest for sustainable and environmentally friendly PCB designs, the utilization of reusable materials is of utmost importance. Let’s dive deeper into how SPICE simulation and PSpice can be our trusty sidekicks in optimizing material usage and fostering a circular economy.

Embrace the power of SPICE simulations for sustainable PCB design. Reduce e-waste, boost energy efficiency, and optimize materials with precision. Let’s revolutionize the electronics industry and create a greener future.