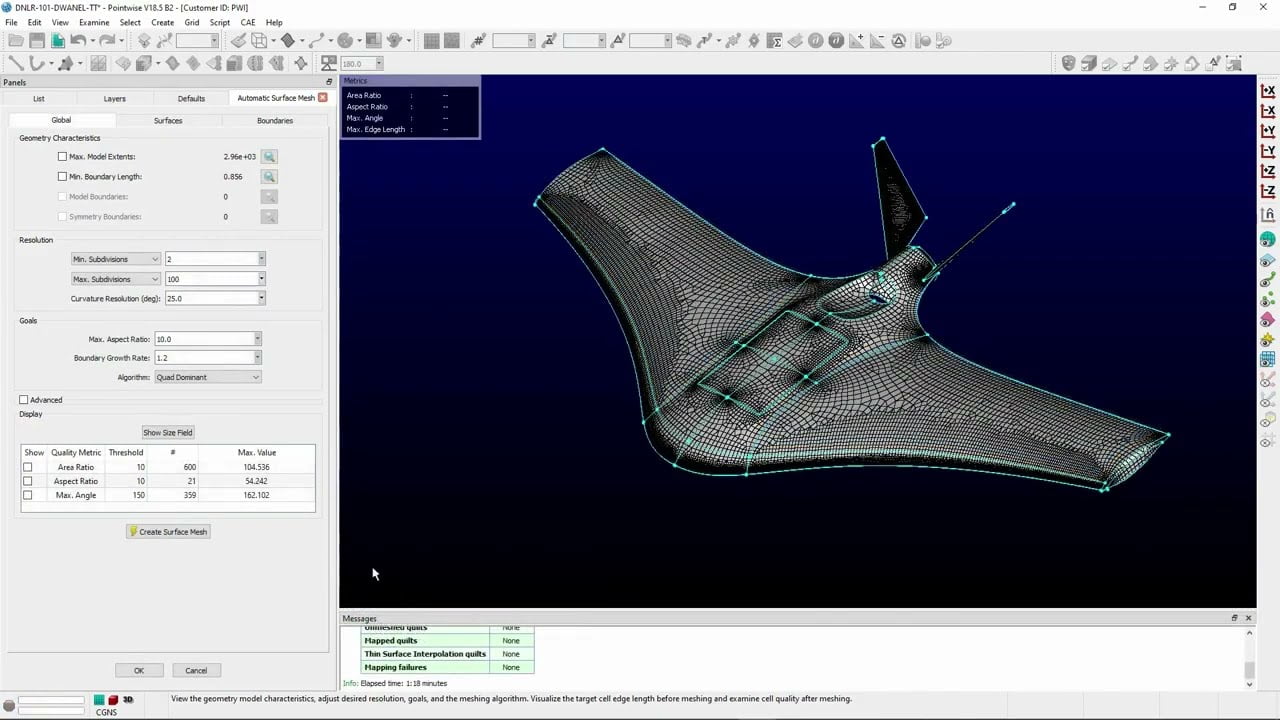

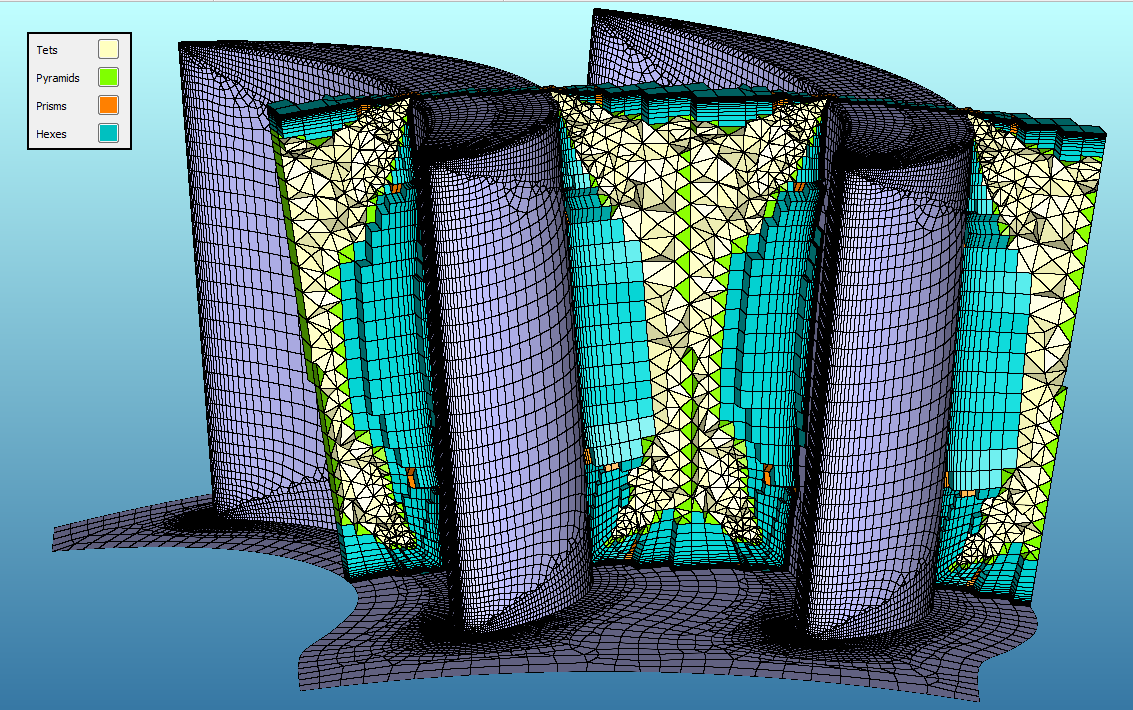

Mesh generation is the most time-intensive part of the CFD workflow with one of the highest impacts. We know that the process can be time-intensive but is vital to ensuring high-accuracy and high-efficiency CFD simulations moving forward.

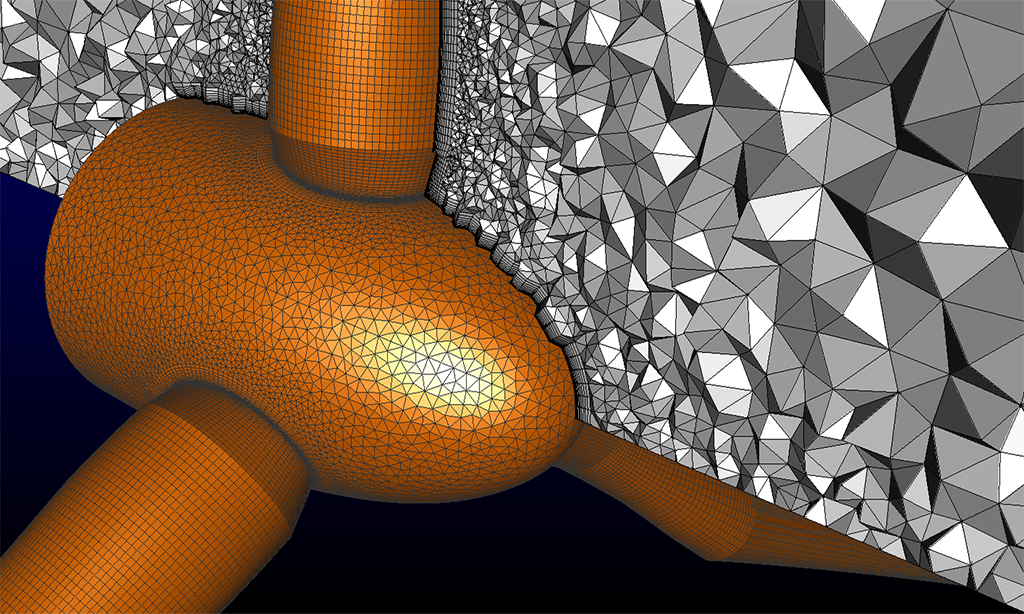

Computational fluid dynamics (CFD) is used in today’s design processes to improve and increase the efficiency without relying on time-consuming and expensive physical testing. One of the biggest challenges engineers face in their daily work is still spent on geometry pre-processing and mesh generation - up to 80% of the engineering time to be exact.

Poor quality CAD or highly complex geometries require lengthy preparation and set-up time and a lot of manual input for a high-quality mesh.

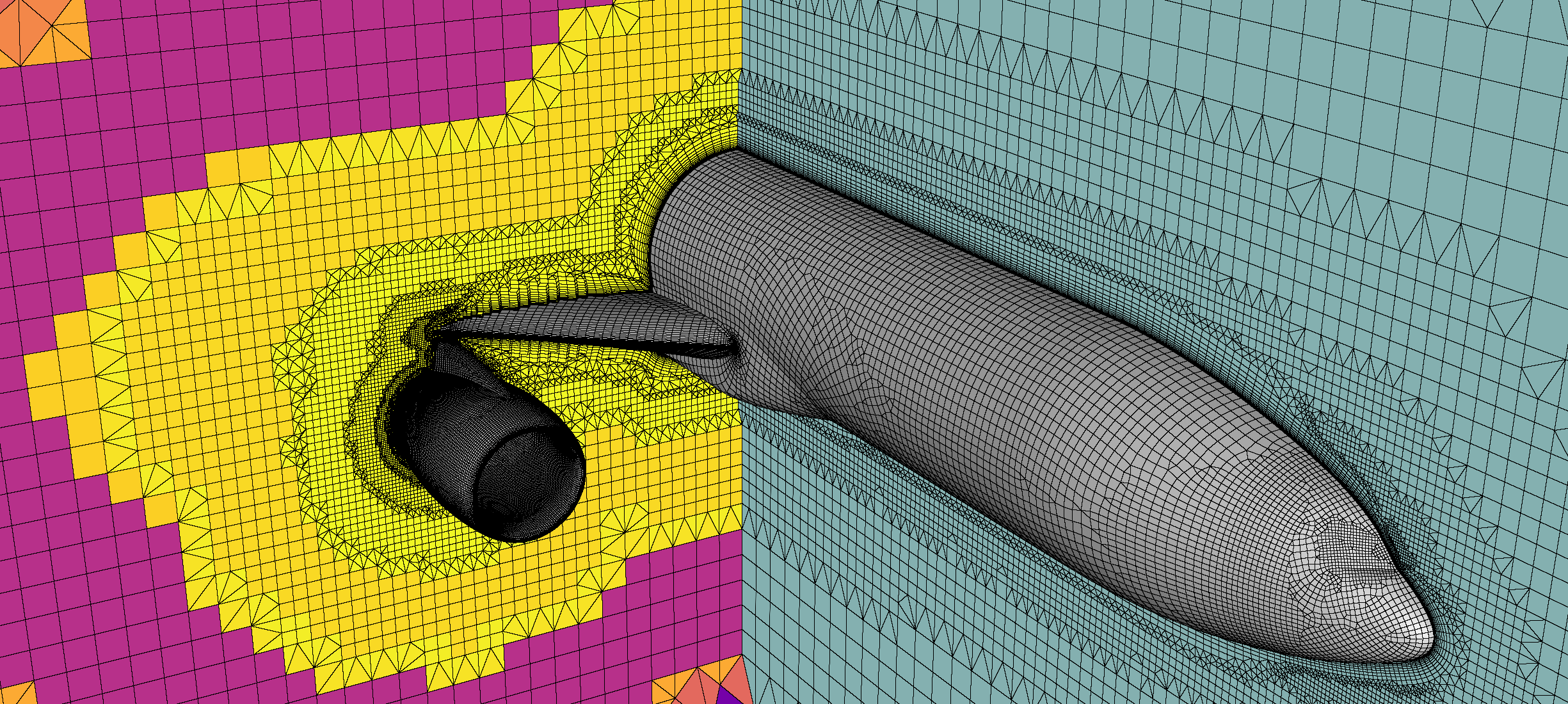

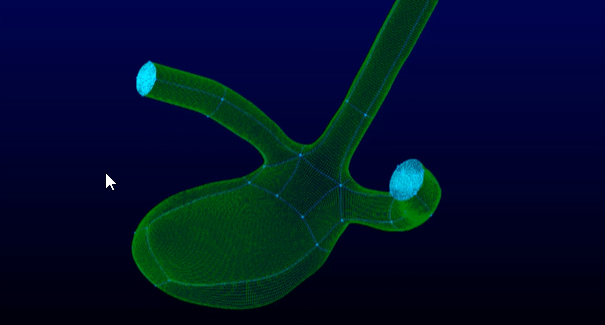

Today, you can automate the entire clean-up and sealing process without losing any detail of the geometry. Even the most complex geometries, which used to take a week of intensive manual work to prepare, now take less than a day to be fully preprocessed—without simplifying the underlying geometry.

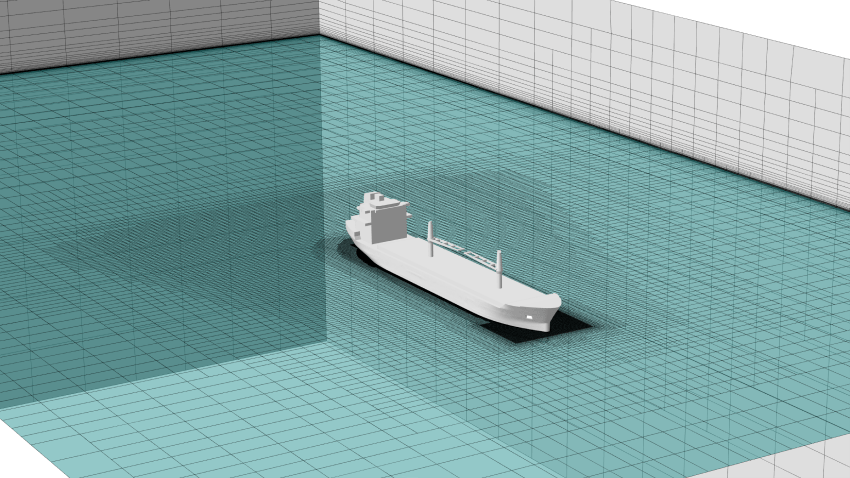

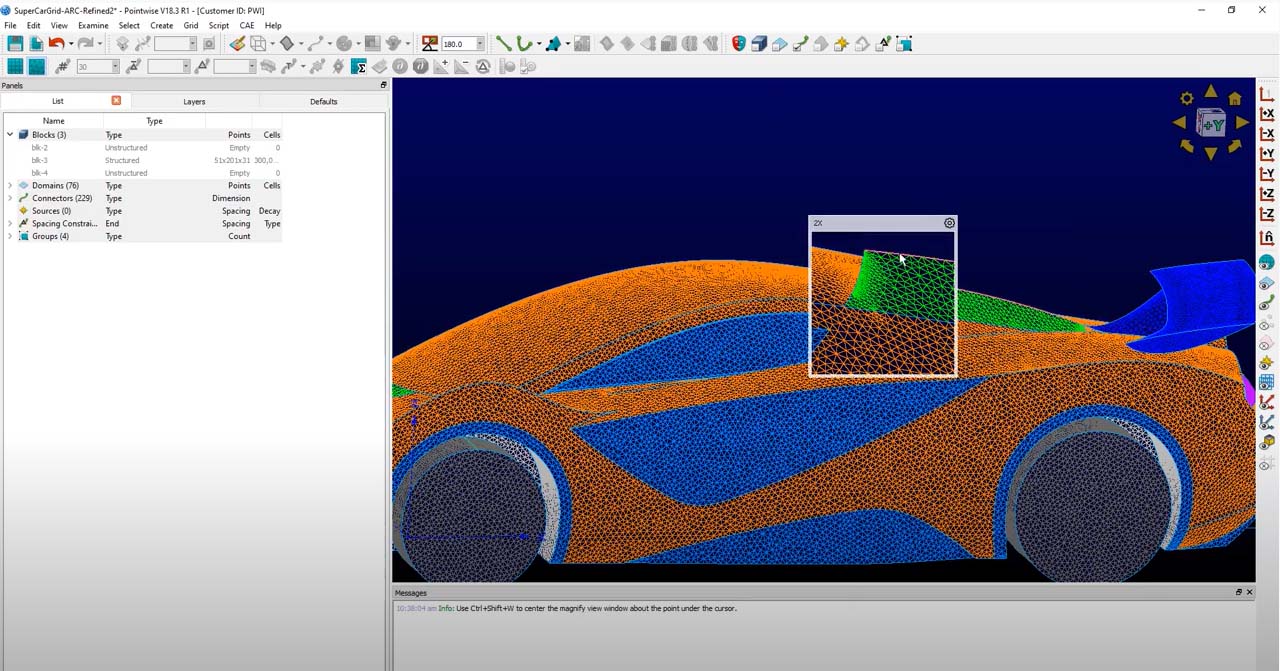

Meshing isn't confined to one field; it's a versatile technique applied across various industries. From aerospace to automotive, marine to energy, CFD mesh generation plays a pivotal role in understanding fluid dynamics, optimizing designs, and making informed decisions.

CFD mesh generation is the bridge that connects theoretical models to real-world applications. It ensures simulations are not just simulations but powerful tools for innovation, problem-solving, and achieving engineering excellence. Pointwise, with its user-friendly interface and robust features, amplifies this value, making mesh generation accessible and efficient for engineers across the globe.

It is not uncommon for CFD engineers to simplify complex shapes to make meshing easier. While this can save time, it often sacrifices the precision of their simulations, impacting performance. Learn more about: