With our integration, you connect OrCAD CIP and Highstage PLM, ensuring all your data is always synchronized—eliminating duplicate work, errors, and uncertainty about component status. In short, you gain full control over your component data, BOMs, and lifecycle status—without manual processes.

You may have experienced these challenges firsthand. In our experience, when OrCAD and PLM are not connected, the following issues arise:

Imagine you work on a new PCB design:

Instead of using hours on manual typework, you have streamlined a reliable flow in minutes.

Our integration between OrCAD CIP and Highstage PLM creates a seamless process where:

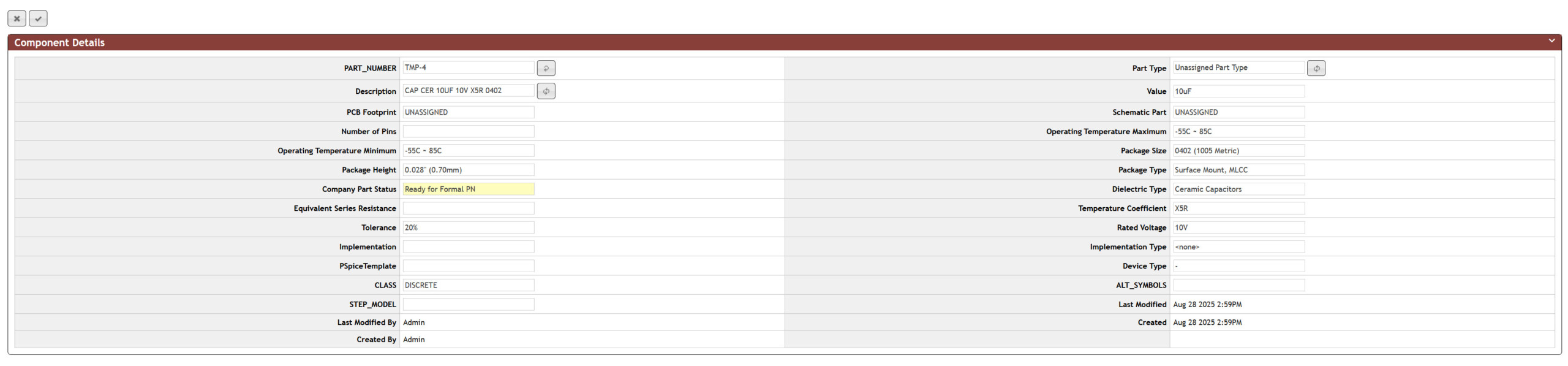

Picture: Editing of TMP component, where Company Part Status is changed to "Ready for formal PN".

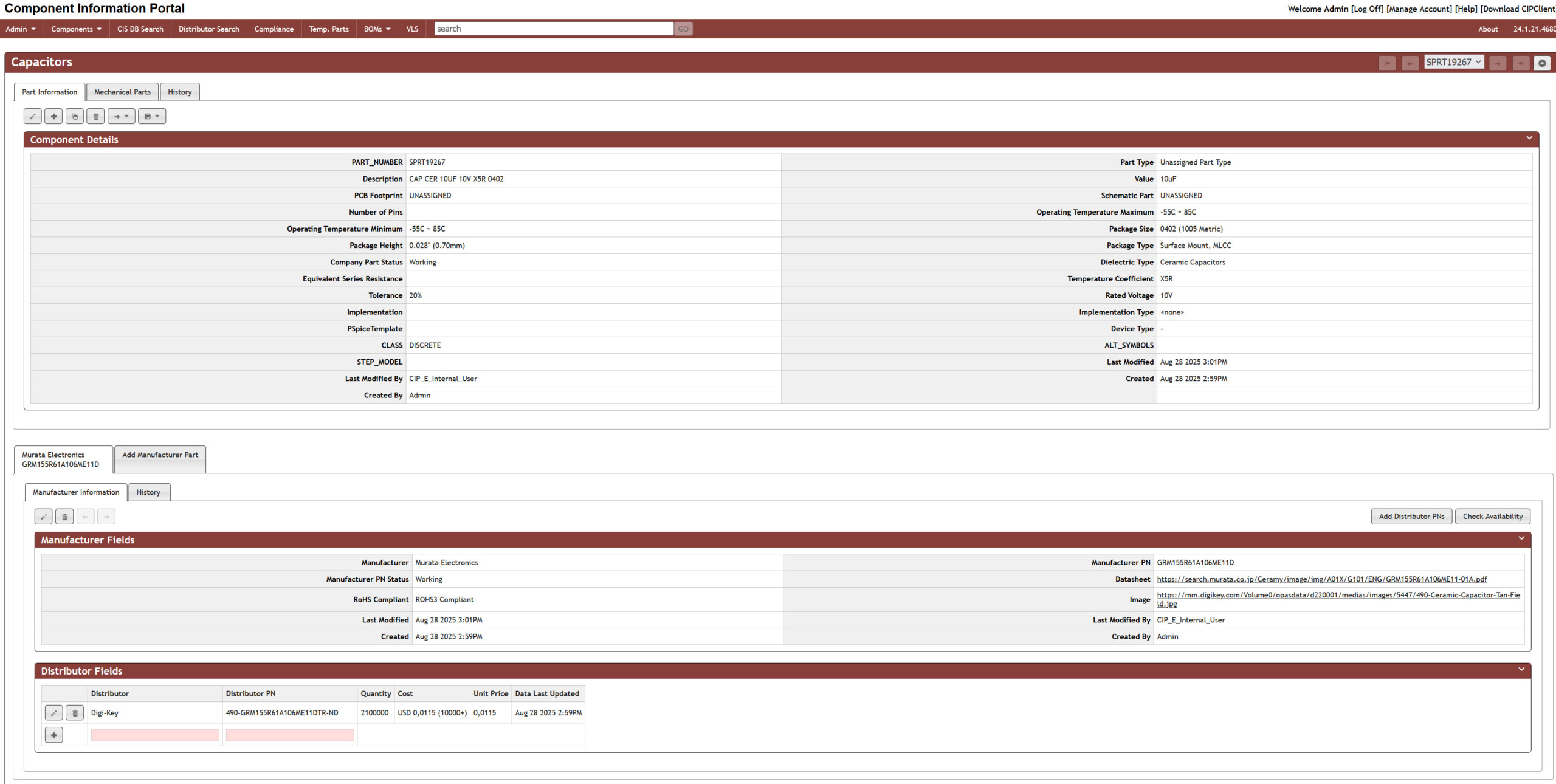

Picture: The execution of the job “HSCIPFormalizeTempPartsSyncJob” in HighStage (which runs automatically every minute) creates the component. You can now see that the component’s part_number has been changed to SPRT19267 and the Company Part Status updated to “Working”.

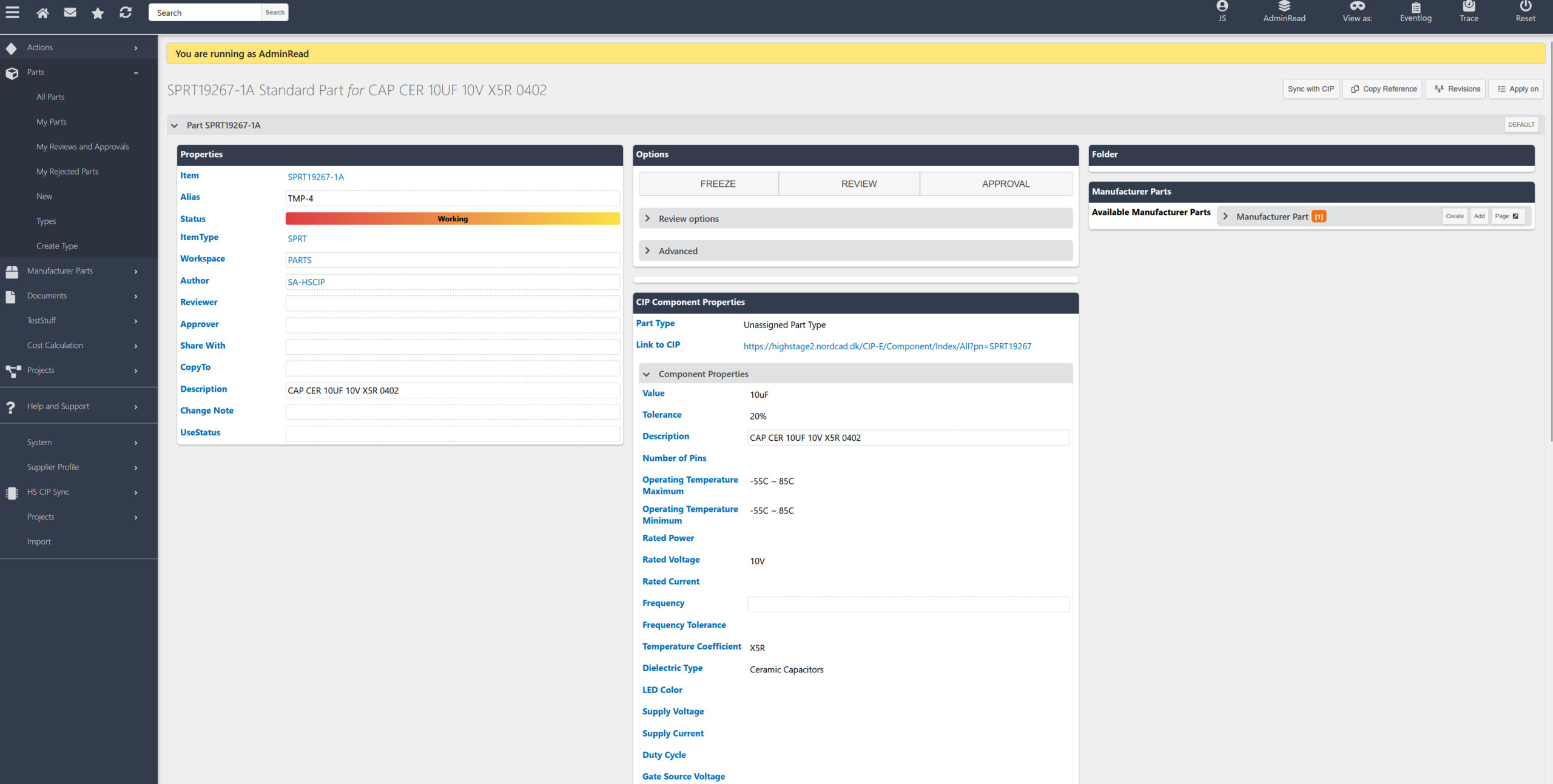

Picture: Here you can see that the component is now in Highstage.

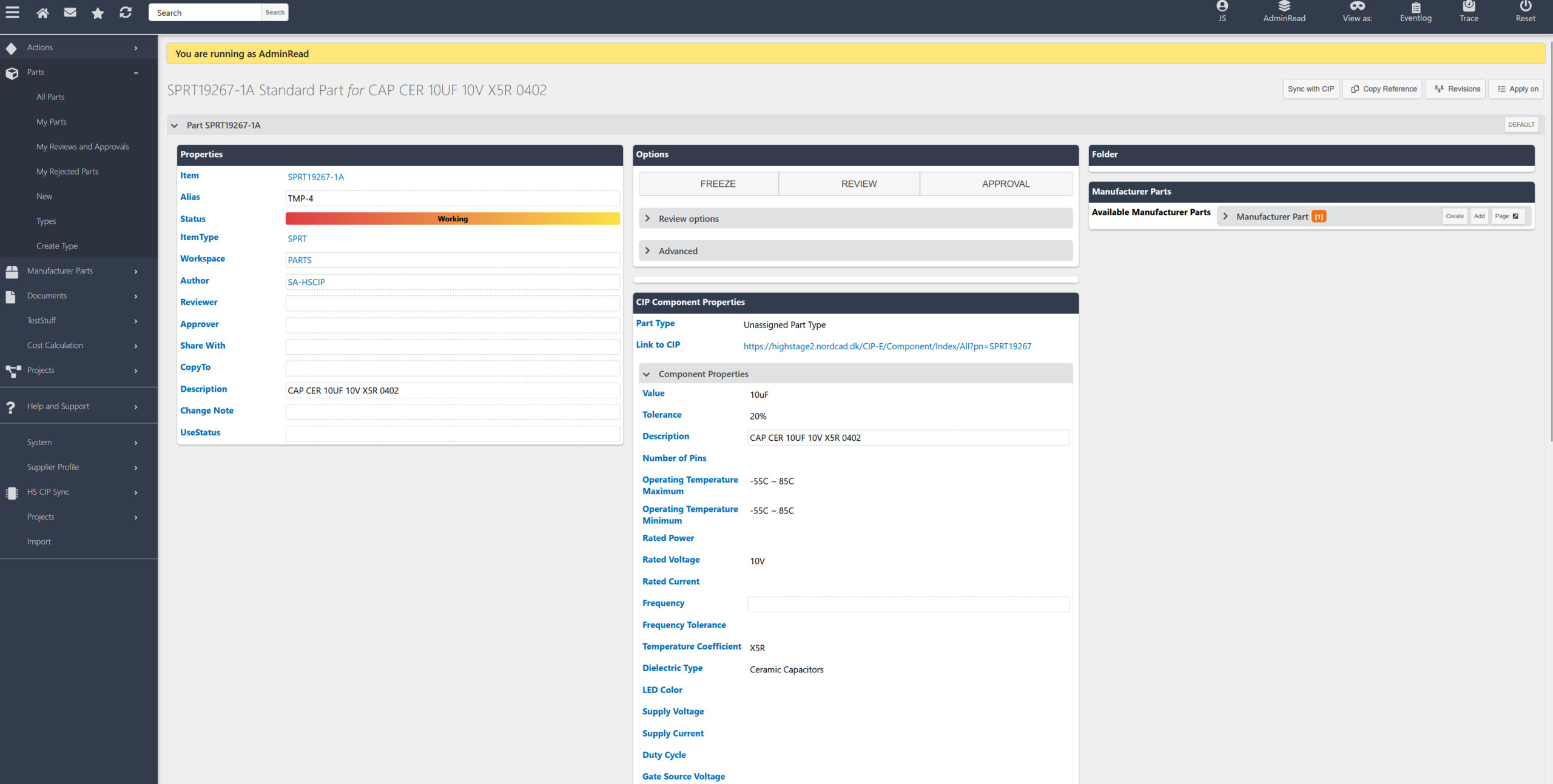

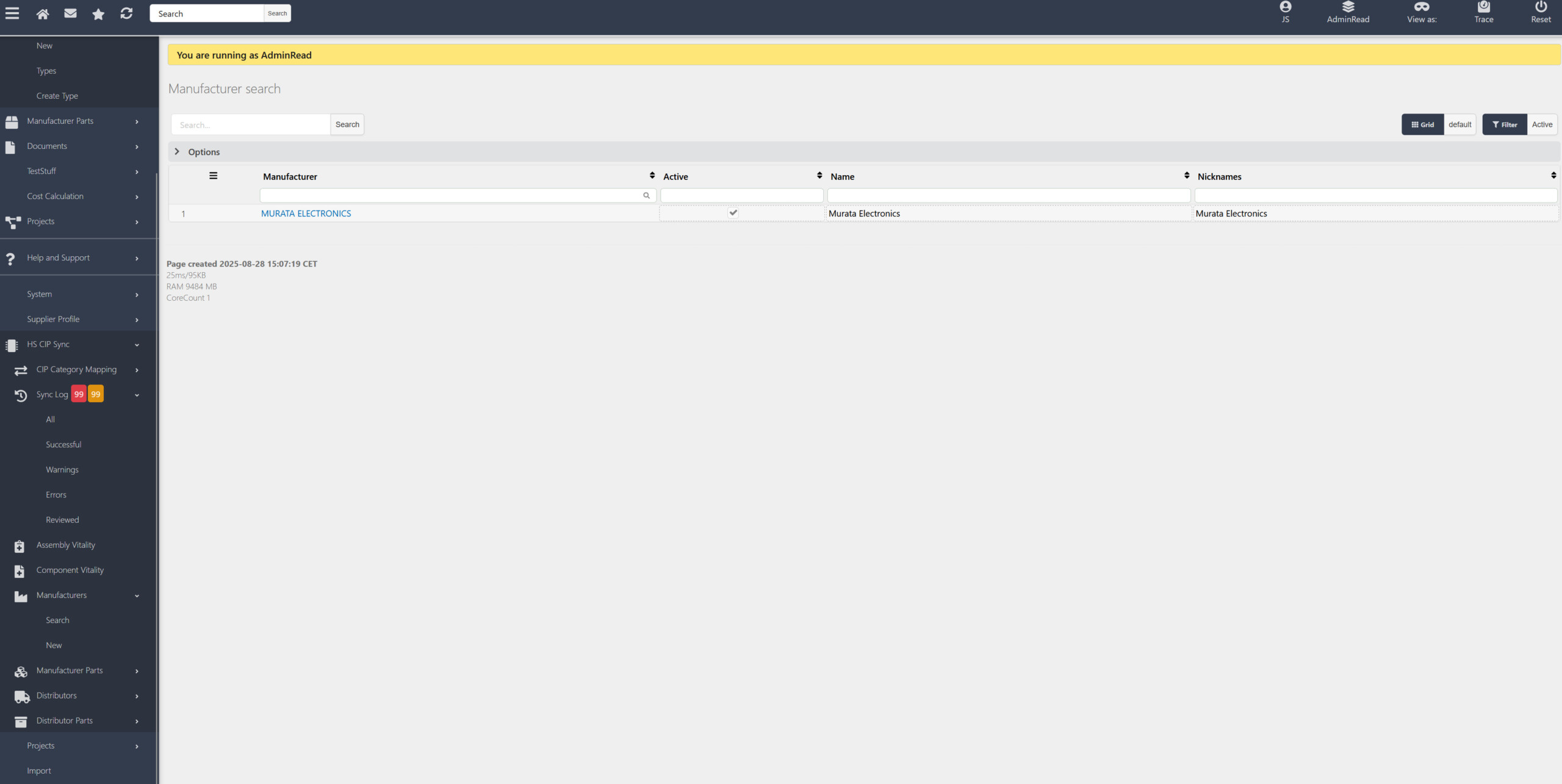

Picture: And here, you can see the manufacturer that makes the manufacturer_parts for our component - also in Highstage.

If it sounds interesting to you and your company, you are always welcome to book a demo or contact us for a non-binding offer.