PCB design complexity continues to increase. Component densities exceed 10 pins per square centimeter. Signal speeds push past 5 GHz. Traditional placement methods struggle with these demands.

Modern PCB designs present extraordinary complexity. Consider a recent 32-layer PCB with 11,635 components, featuring eight custom ASICs with 2,116 pins each. This board required nearly 3,000 hours to complete, with design decisions driven by multi-gigahertz signal speeds and power requirements exceeding thousands of watts. Such complexity challenges even experienced design teams.

Traditional PCB design relies heavily on manual placement and routing, supported by rules of thumb and design patterns. However, these practices often lack physics-based validation and may not represent optimal solutions. The design process involves multiple interdependent analyses—electrical, thermal, mechanical, and manufacturing—creating a multi-objective optimization problem that exceeds human capability to solve efficiently.

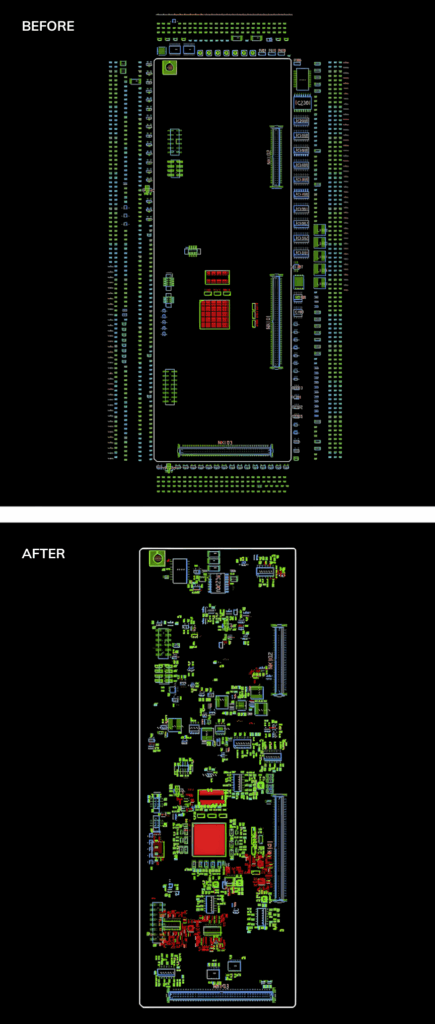

Allegro X AI takes a different approach. Instead of rule-based automation, it uses machine learning trained on successful designs. The system makes placement decisions based on patterns from thousands of completed projects.

Why Manual Placement Hits Limits

Modern designs present specific challenges that manual methods cannot efficiently address:

- Component density. Credit-card-sized boards now hold over 1,000 components. Each placement decision affects routing feasibility.

- Signal integrity requirements. High-speed signals demand precise component positioning for impedance control and crosstalk management.

- Multi-objective optimization. Designs must satisfy electrical, thermal, mechanical, and manufacturing constraints simultaneously.

- Time pressure. Development cycles leave insufficient time for comprehensive design exploration.

Traditional auto-routers follow predetermined algorithms. They cannot adapt to unique design challenges or learn from successful solutions. This creates a bottleneck in the design flow.

How AI Changes the Process

Allegro X AI addresses PCB design complexity through a novel approach combining large-scale search algorithms with learned evaluation networks. The system operates as an iterative feedback loop: a feed-forward process generates initial designs, then feedback mechanisms drive continuous improvement until optimal solutions emerge.

Allegro X AI employs several technologies working together:

Neural networks analyze component relationships and physical constraints to make informed placement decisions.

Physics-based simulation provides real-time electromagnetic and thermal feedback during placement.

Cloud computing enables exploration of thousands of design alternatives simultaneously.

The system processes design constraints and generates optimized component placement in minutes rather than hours.

Real-World Testing Results

Danfoss, a global leader in energy-efficient solutions, implemented Allegro X AI to address challenges in designing complex control systems and IoT-enabled devices.

Implementation Approach

Danfoss deployed Allegro X AI across their PCB design workflow with:

- Comprehensive engineer training programs

- Custom AI model development for Danfoss-specific requirements

- Integration with existing design processes

- Continuous model refinement based on design outcomes

Quantified Results

Allegro X AI was first tested on a representative mixed-signal design:

- 511 components

- 1759 connections

- A pin density of 86.827 pins/cm2

- 4-layer board

- 20 power nets

- Complex spacing constraints

Time Comparison

| Task | Manual Time | AI-Assisted Time | Improvement |

|---|---|---|---|

| Component Placement | 60 minutes | 2 minutes | 96% reduction |

| Total Process | 70 minutes | 25 minutes | 64% reduction |

The AI setup added 5 minutes to the standard 10-minute configuration time. This overhead is minimal compared to the time savings achieved.

Quality Assessment

The AI-generated placement received a 4/5 rating from experienced designers.

Strengths observed:

- HDMI decoder positioned correctly adjacent to connector

- Excellent component alignment across layers

- All critical constraints satisfied without violations

Areas for improvement:

- Some discrete components placed on bottom layer when top-side placement would improve assembly

- Tight packing within defined areas created potential routing challenges

Engineering Impact

Beyond quantitative metrics, Danfoss engineers reported improved collaboration between global teams, consistent design standards across projects, and reduced learning curves for new team members. Allegro X AI enabled engineers to focus on high-level design innovation rather than routine optimization tasks.

Implementation Guidelines

Getting Allegro X AI to work effectively comes down to how well you communicate your design intent. The system operates like an experienced designer who needs complete information to make good decisions. Incomplete or ambiguous constraints lead to suboptimal results, just as they would with a human designer.

- The constraint setup process requires more upfront thinking than traditional tools. You define not just what components go where, but why they belong in specific relationships.

- Power and ground net definitions establish the electrical foundation.

- Component spacing requirements tell the AI about mechanical and thermal considerations.

- Layer assignment preferences communicate assembly constraints.

- Functional groupings explain signal flow and operational relationships.

This comprehensive approach pays dividends during placement. The Danfoss study showed that spending 15 minutes on thorough constraint definition enabled Allegro X AI to complete placement in 2 minutes rather than the 60 minutes required manually. The time investment shifts from execution to specification.

Consider discrete component preferences carefully. Setting resistors and capacitors to "Top Only" rather than "Both" sides improves assembly efficiency and reduces manufacturing costs. The AI will honor these preferences while optimizing for electrical performance. Start with broader spacing constraints and observe how the system responds. You can progressively tighten requirements as you understand the AI's decision-making patterns.

Functional relationships matter more than rigid geometric constraints. When you define that an HDMI decoder should stay close to its connector, the AI understands signal integrity requirements and places components accordingly. This approach produces better results than specifying exact coordinate positions.

The iterative refinement process becomes a learning experience. Each AI-generated placement reveals something about your constraint specification. Use these insights to improve subsequent runs rather than manually adjusting the initial result.

System Scope and Limits

Allegro X AI handles designs up to 5,100 components at densities reaching 100 pins per square centimeter. These limits cover most commercial PCB applications while maintaining processing speed and solution quality. The component count accommodates complex mixed-signal designs, high-performance computing boards, and multi-function consumer electronics.

Density limits reflect practical PCB manufacturing and assembly constraints rather than AI processing limitations. Boards approaching 100 pins per square centimeter require advanced manufacturing processes and present significant routing challenges regardless of placement quality. Allegro X AI performs optimally within these realistic boundaries.

Complex constraint handling supports demanding applications. High-speed digital designs benefit from impedance-aware placement. Mixed-signal boards get appropriate isolation between analog and digital sections. Power electronics applications receive thermal optimization. The system adapts to application requirements rather than forcing designs into predetermined patterns.

Engineering & Business Impact

The productivity improvements extend beyond simple time savings. Design teams complete more projects with existing resources. Engineering time shifts from routine placement tasks toward creative problem-solving and optimization. This reallocation improves job satisfaction and produces better end products.

Quality consistency eliminates the variability between different designers working on similar projects. A junior engineer using AI assistance produces placement quality comparable to senior team members. This democratization of design expertise accelerates team development and reduces training requirements.

The time savings compound across design iterations. Faster placement enables more design exploration within project schedules. Teams can evaluate multiple architectural approaches, optimize for different objectives, and respond to late specification changes without schedule impact.

Preparing Your Organization

Technical infrastructure requirements go beyond software installation. Design rule standardization becomes critical when AI systems interpret and apply constraints automatically. Inconsistent or incomplete design rules that human designers might work around will cause AI performance problems.

Systematic constraint documentation processes replace ad-hoc specification methods. Teams develop templates and checklists ensuring complete design intent capture. This documentation benefits human designers as well, improving overall design quality and reducing errors.

Cloud connectivity requirements depend on design complexity and usage patterns. Large designs or frequent AI usage benefit from dedicated high-bandwidth connections. Occasional use of smaller designs works adequately with standard internet connections.

Integration testing with existing tool chains prevents workflow disruptions. Verify that AI-generated placement data transfers correctly to routing tools, simulation environments, and manufacturing systems. Test version control integration and collaborative design workflows.

Organizational readiness involves cultural adaptation as much as technical preparation. Engineers learn to think in terms of design objectives rather than implementation details. This shift requires training and practice but ultimately produces more effective designers who focus on what matters rather than how to achieve it.

Quality assurance processes adapt to evaluate AI-generated designs appropriately. Traditional placement review focused on catching human errors and oversights. AI-assisted placement review focuses on validating that the system correctly interpreted design requirements and produced results aligned with project objectives.

Looking Forward

Allegro X AI fundamentally transforms PCB design from a manual, experience-based process to an automated, physics-driven optimization system. By combining advanced machine learning with comprehensive design analysis, it delivers measurable improvements in design quality, development speed, and engineering productivity.

The system works best as a design amplifier rather than a replacement for engineering judgment. Proper setup and constraint definition remain crucial for success. As demonstrated through real-world implementations like Danfoss, organizations achieve significant competitive advantages through faster development cycles, improved design quality, and reduced engineering overhead.

This represents the next evolution in electronic design automation—moving from rule-based assistance to intelligent design partnership.

The shift from manual to AI-assisted placement changes how we approach PCB design. Early adoption and proper implementation provide competitive advantages in engineering productivity and time-to-market performance.