Product Lifecycle Management is a system that connects people, data, and processes across every stage of product development. From early concepts and requirements to production, maintenance, and end-of-life, it gives your organization a single, structured environment for managing all product information.

For engineering teams working with complex PCB designs and multi-domain systems, PLM software ensures data integrity, version control, and collaboration between design, mechanical, and manufacturing teams. In short: it helps you develop products faster, with fewer errors and clearer documentation.

Traditionally, many development teams have tried to manage their data using simple PDM solutions, network folders, or manual workflows. However, as demands for traceability, documentation, and cross-functional collaboration increase, these approaches are no longer sufficient.

The system provides:

Especially in the electronics industry, where component data, BOMs (Bill of Materials), ECAD files, and compliance requirements must be correctly updated and documented, Product Lifecycle Management is a necessity rather than a luxury.

Without a unified system, engineers often face version mismatches, data silos, and manual rework.

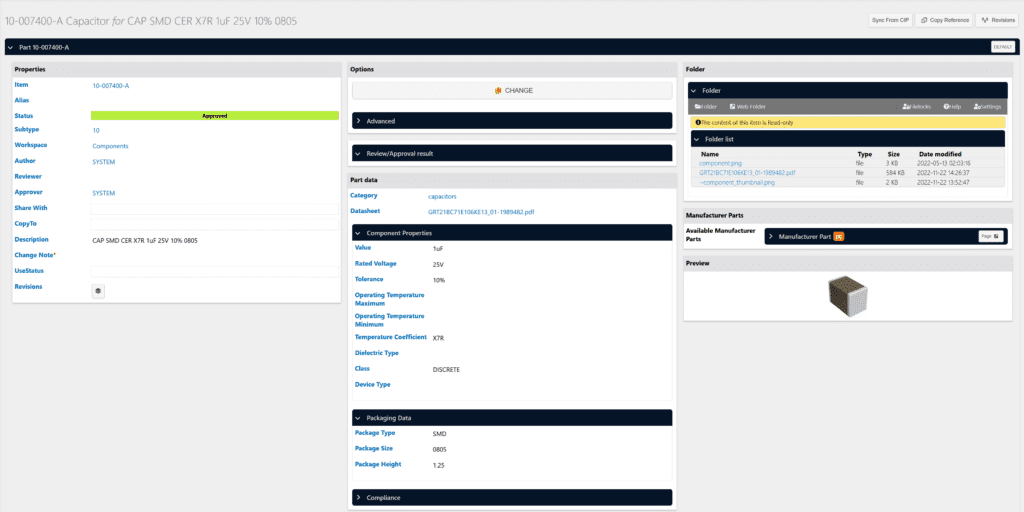

The software acts as the single source of truth for all product-related information. It connects directly with ECAD, MCAD, and ERP tools to synchronize data and maintain consistency across domains.

In a typical electronics development environment, a PLM system will:

By bridging data between engineering, procurement, and production, it helps teams make informed decisions faster.

It is important to understand the differences between these three system types:

In modern electronics development, integration between PLM and ECAD tools is critical. When the system is directly connected to your ECAD platform (e.g., OrCAD or Allegro), you can:

Nordcad provides solutions that integrate Cadence tools with recognized PLM platforms, supporting your entire workflow from concept to production.

It is not just for large enterprises. Small and medium-sized companies working with complex electronics can also gain significant value from a well-implemented system. It’s not about company size – it’s about complexity and the need for oversight and quality.

Typical users include:

In complex electronics projects with many components, design phases, and collaborators, it’s easy to lose oversight. Product Lifecycle Management helps consolidate all relevant data in one place and ensures that every decision and change is properly documented.

With it, development teams can:

A successful PLM implementation starts with understanding your current workflows. Map out how data moves between design tools, spreadsheets, and departments. Identify where errors or delays occur — those are your opportunities for improvement.

Practical steps to begin:

Nordcad offers the platform Highstage which integrates directly with OrCAD and Allegro environments, enabling engineers to manage product data without leaving their design tools.

Want to see how it can optimize electronics projects in practice? Our short demo shows how workflow, BOM management, and version control function in a modern product management tool.

Watch our webinars on PLM and product management.

Read our articles for hands-on tips and real-life cases.